With vision to pioneering weld seam inspection

Reliable weld seams are important for piping systems in the semiconductor industry. To check this quality, SCS has developed an innovative vision inspection for its customer Georg Fischer.

-

Problem

In the semiconductor industry, reliable welds on pipes are extremely important. If one spot leaks, the factory has to be stopped, which has very big financial consequences.

-

Solution SCS

In order to analyse and verify the quality of welds, SCS has developed suitable imaging methods and algorithms.

-

Added value

Based on SCS's work, the client was able to further develop the project into a product. This won second place in the IVS Innovation Award 2019 and was launched in February 2020.

Project insights

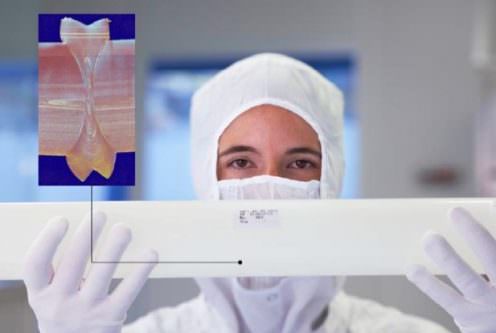

The customer Georg Fischer offers a wide range of products that enable pipes to be welded together (Fig. 1). The pipes are welded by heating and pressing them together. Molten material emerges at the pressing point (cross-section Fig. 2). For a quality control of such welds, possible solutions were developed together with the customer. The ideas for solutions created in the innovation workshop formed the basis for a feasibility study, which SCS carried out.

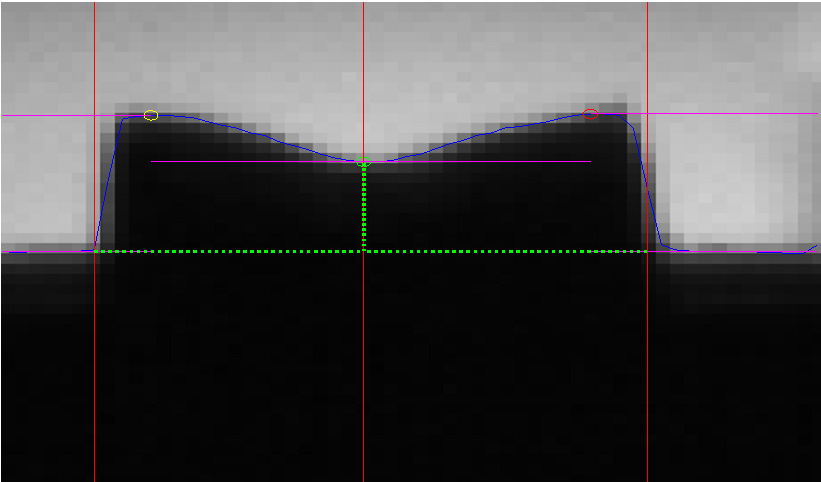

The aim of the study was to develop a method with which different quality characteristics of a weld seam could be determined. For example, the thickness of the weld seam, the pipe offset, etc. should be detected.

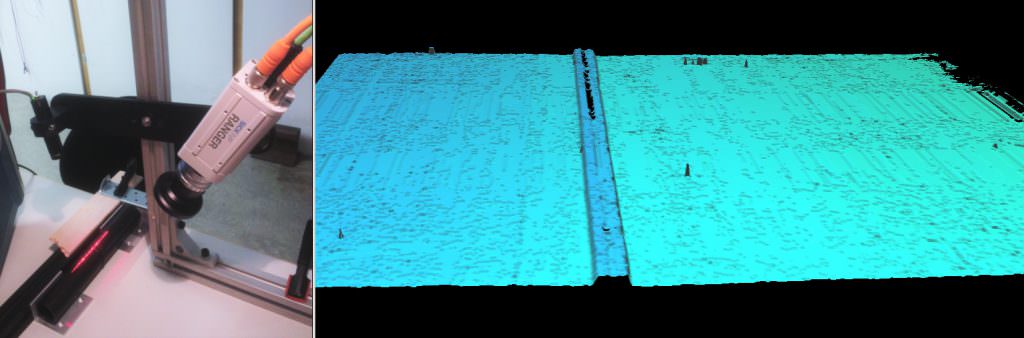

In the feasibility study, different procedures and algorithms were developed and tested. In the SCS vision lab, ideas were elaborated, difficulties discussed and best possible solutions worked out. The test setups enabled a quick evaluation of the different approaches and their feasibility. For example, the experimental setup with a laser (Fig. 3) looked promising at first, but was quickly discarded thanks to a short iteration cycle. It turned out that the different optical properties of the tube materials were not suitable for quality control with lasers.

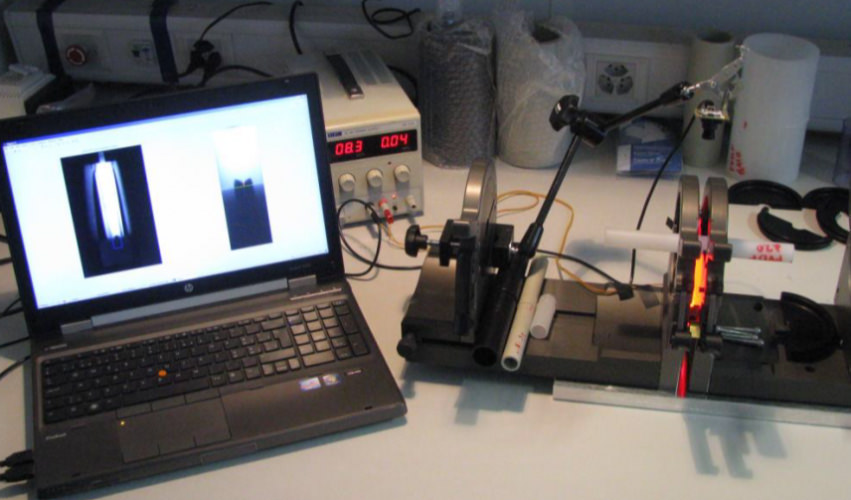

Therefore, the current solution uses transmitted light so that similar images are provided for different materials. This set-up made it possible to use low-cost camera modules and illumination (Fig. 4). This solution is therefore simpler and delivers very good results.

The captured images were finally analysed and evaluated by a classical vision algorithm. The vision algorithm analyses the different dimensions and determines the weld seam quality (Fig. 5).